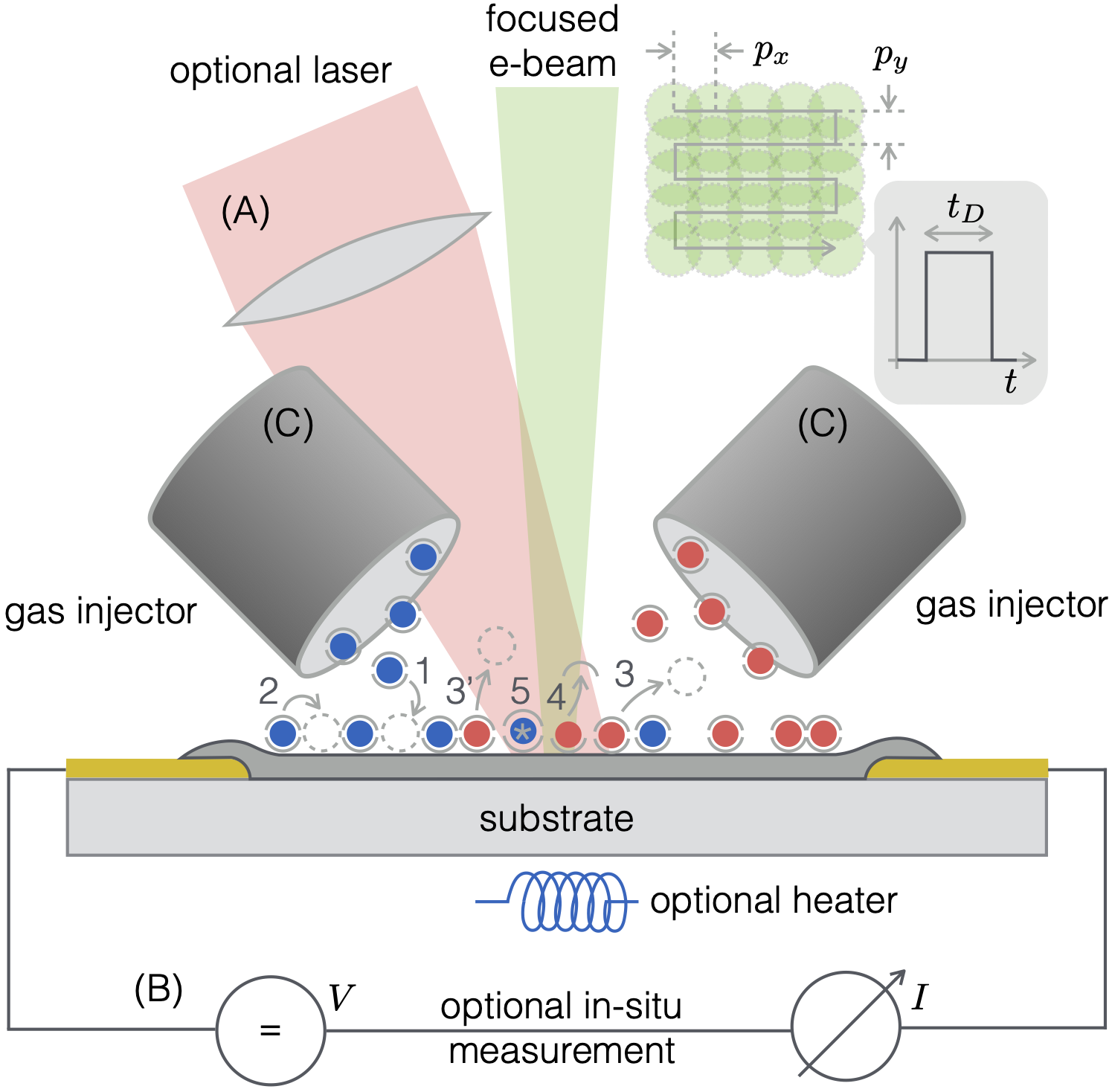

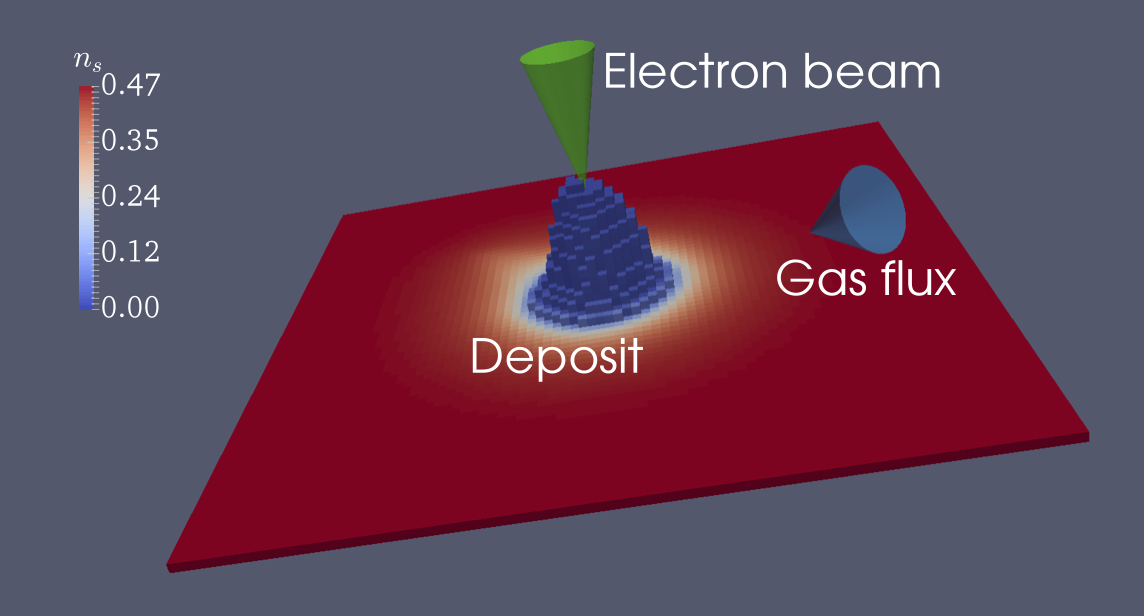

The basic principle of FEBID is simple. Provided by a gas injection system (GIS) or an environmental chamber inside of an

electron microscope, a precursor gas adsorbed on a surface is dissociated in the focus of an electron beam.

This brief description shows an apparent conceptual similarity to 3D-printing, in particular if one considers

the 3D writing capabilities of FEBID.

A closer look, however, reveals the intrinsic complexity of the process. The electron-induced dissociation process is

mostly triggered by low-energy electrons, i.e. the secondary electrons generated by the primary electrons SEI)

and also by the backscattered electrons (SE II). For the process several dissociation channels are available with

strongly energy-dependent and precursor-specific cross-sections. Which precursor to choose for a given application

has to be carefully considered, as the growth process depends on several precursor-specific aspects, such as its vapor

pressure at around room temperature, the adsorption characteristics of the precursor molecules and the stability of

their stability under adsorption.